A Sailor’s Journey – Bring The Wind Sailing

Before I was born, my family was already sailing Georgian Bay in Lake Huron, Ontario on a Tanzer 26. When I came along as the youngest of 4 boys my parents were diagnosed with “2 footitis” and they transitioned to a 30 foot 1982 Nordica. My dad was always bringing his old school camcorder with us to create home videos of our sailing trips. As a young adult I purchased my first sailboat and continued the family tradition. It wasn’t until years later that I stumbled upon those VHS tapes containing the videos and all of those memories came back to me. This inspired me to begin to capture my family’s sailing adventures on youtube, at first privately, but now publicly.

After some trial and error on finding my perfect sailboat, I finally stumbled across The Julia D, my Tanzer 7.5 on an acreage amongst the foothills of Sundre, Alberta. At the time, I had a motorbike with no use to me that was recently restored. I got in contact with the owner of the Tanzer and we worked together to come to an agreement of a straight across trade, motorbike for sailboat.

During this exchange, I learned some valuable information about my Tanzer. To start, the name of the boat was already The Julia D, which was named after the wife of the first owner and the sailboat had originated from Manitoulin Island, Ontario. Fun fact: Manitoulin Island was one of the many destinations we would sail to during my childhood. Both the previous owner and I decided to keep the name the same. Next, I learned that the current owner of the Tanzer was a carpenter, that he and his step father had completely redone the interior of the sailboat for a few years but the carpenter lacked any sailing skills or experience. Instead, it was his step father that was the sailor and when he unfortunately passed away, the son decided that he would part ways with their beloved Tanzer 7.5. The plan was to sail together.

After receiving my new-to-me sailboat, I knew I wanted to convert the trailer to have a keel guide to assist with the haul out and launch. Where I am in Saskatchewan we don’t have cranes to lift the boats out of the water but do have a travel lift and tractor that is operated by members of the lift company (us). The use of a trailer is less stressful and saves time. After the conversion was complete, my Tanzer was still equipped with hank-on sails, which I was used to as my previous boats and my parents boat were the same.

During some time watching YouTube, I realized that not only should I start shopping for a new Tanzer 7.5 headsail, but a lot of the sailing channels are running a furling system on their boats. I decided to contact Precision Sails to order a new 115% jib and during that time I asked for their opinion on furling systems, to which they recommended for me to look into CDI Flexible Furlers.

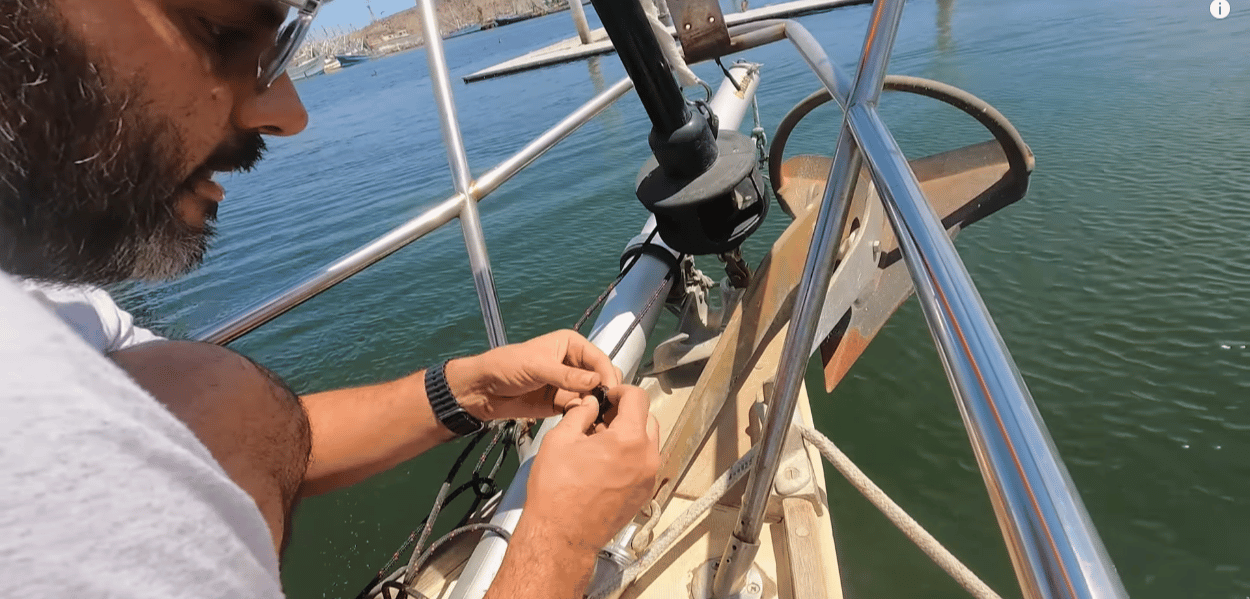

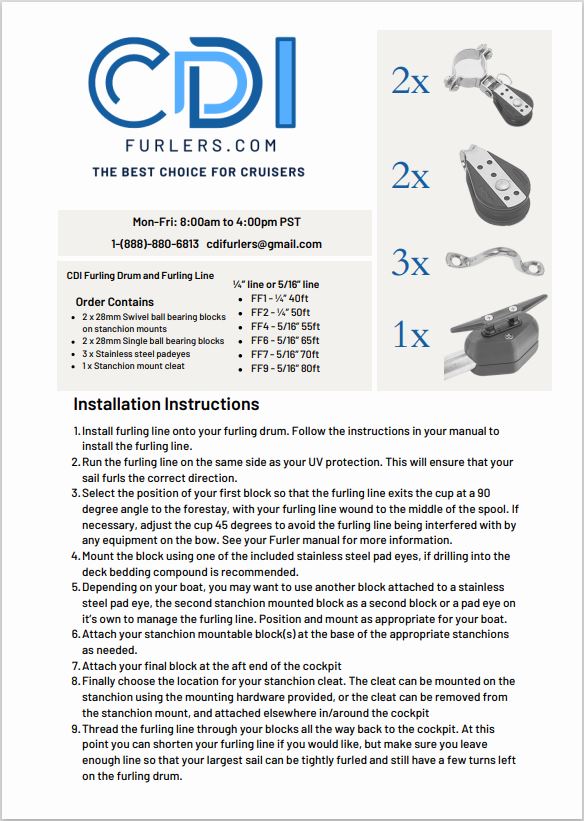

I found the CDI Flexible Furler FF2 to be a great option for me, after some research, due to its ability to be installed over the existing stay and being a DIY friendly option. Once it came in and it was time to install, I invited one of my brothers over to help out with installing the CDI Furler and Precision Sails headsail at the same time.

The installation wasn’t too difficult, but we found the most difficult part being the adjustments in order to get everything perfect. We also found that the instructions that came with the furler were a little difficult to follow, but after a recent phone call with some of the staff at CDI Furlers, I was informed that they are planning to come out with in-depth installation videos which will be a huge help!

After all was complete, it was time to sail, and I couldn’t be happier with both products, the furler and the new sail. Not only is it easier for me to sail solo, but it’s also much easier for me to sail with my children as I can now adjust my foresail from the cockpit instead of having to go to the front of the bow to drop the fore sail and bag.

During my call with the CDI Furlers team, I was asked what a few tips would be to other sailors looking to install a CDI Flexible Furler.

- Take as many photos and videos as possible! Keep them in an album on your phone because if you are like me and need to put up and take down your sails every season, these will help you remember what you did right, and more importantly, what you don’t want to do.

- Make sure to remember which way your sail needs to furl. I made this mistake and installed my sail to furl the wrong way which ended up causing the sacrificial UV strip to be covered. It’s a bit of a pain to undo and redo everything a second time.

- When setting up your sails with the furler, think of your forestay as a clothesline. Attach a messenger line or mast line to close the loop with your sails attached at the bottom. From there, you can just hoist the sails up like a clothesline.

I still think about the carpenter and his late step father from time to time when I’m enjoying The Julia D. My plan is to have the carpenter out to Lake Diefenbaker to see what I have done to improve her while taking him for a sail one weekend bringing everything full circle for him and his late step father.