Mainsail Furler Installation Help

Installing Your Mainsail Furler

1) Place the extrusion on the ground

2) Stand on the inside of the taped up circular luff so the luff doesn’t spring open and hit you when the tape is cut

3) There will be bands of tape all down the luff. Starting with the tape closest to the end of the luff extrusion, cut the tape and carefully uncoil to the next band of tape

4) While holding the untapped portion of the luff, carefully slice the next band of tape

5) Continue this process until there is only one tape band remaining. Stop before cutting the final band.

6) You will need 1-2 helpers for the final step. Your helpers should hold the luff, both the coiled portion, and the uncoiled. When ready, cut the last tape band, and carefully allow the luff to assume its natural curve.

Important Notes

-Weighing the luff down flat on the ground and/or trying to straighten with a hair dryer will not work and will void your warranty! You must follow the instructions below.

-You will require some help. You need one person set up every 8 feet along the luff. Avoid twisting the luff, and do not let it sag.

-Please make note that there is a straight end (this was shipped straight) and a curved end.

1) Full instructions with photos are included on your shipping box. Please make sure to fully read these instructions before beginning.

We need to recoil the luff, in the opposite direction that it wants to curve naturally.

2) Tape your curved end to the other end at the point where the luff curve begins.

3) Lay the now taped luff back on the ground. Let it sit for at least 3 hours, at which point you can test to see if it is straight by carefully removing the tape.

4) If the luff still has a noticeable curve you must retape the luff and allow it to continue to sit. The warmer the weather, the faster this will be.

5) Some small curvature is to be expected, and will not affect performance. Your forestay tension will correct a gentle bend.

Important Note: If your luff has been stored incorrectly, coiled, or bent the best way to correct this is to sit the entire luff inside of a tube or pipe and leave the entire thing outside in direct sunlight for 1-2 weeks in the summertime.

Weighing the luff down flat on the ground and/or trying to straighten with a hair dryer will not work and will void your warranty!

Installation

1) Review the parts list and make sure you have everything you need.

2) Thoroughly read the instructions, if you have any questions please reach out to us. You can contact us via phone or email.

Phone: 607-749-4599

Email: [email protected]

3) First we need to install the upper brackets, there are 2 top straps and a top bracket assembly.

3a) The mounting arms on the top bracket assembly must be formed to the mast to match the mast shape.

3b) You may need to form the top straps wider or more narrow to fit your existing masthead. Be careful to bend each Top Strap equally.

3c) The top straps are to be installed by removing either the backstay pin or the main halyard sheave pin. Install the top straps outside of your existing masthead using one of the 5/16” dia. Bolts provided (2” or 2 ½” long as necessary). Secure this with a 5/16’ dia. Nylock nut.

3d) Using the ⅜” dia. X 1 ⅞” long clevis pin, connect the top straps and top bracket assembly

3e) Swivel the top bracket assembly until the stop is against the mast. Center the bracket assembly on the mast slot. Drill and tap through the top bracket assembly into the mast. Fasten with ¼-20 x ⅜” long screws.

4) Next we are installing the lower bracket assembly. Including the lower bracket and the reefing spool assembly

4a) Match your lower bracket mounting surfaces to the approximate mast width. If the mounting services on the bracket need to be closer together place the bolting flanges in a vise and carefully squeeze them together until the width is correct.

4b) Centered on the mast slot, 2 ¼” above the top of the boom you will see the bottom surface of the Lower Bracket. Then find the bracket cup surface, perpendicular to the mast. If the bracket is not perpendicular to the mast the bearings will not freely rotate and it will always be difficult to turn the system. Against the mast you will find the bracket stop flange. Drill and tap through the bracket mounting holes and fasten with ¼-20 x ⅜” long screws. You will see two longer fixture screws included, these may be used to pull the bracket close enough to the mast that the correct ⅜” long screws will mount into the mast. To ensure that the holes line up, we recommend you install each screw as it’s hole is drilled and tapped.

4c) Now we need to figure out if the mainsail reefing line should be mounted on the port or starboard side of the boat. Mount the reefing line sheave on the lower bracket roughly where you want the reefing line routed. If the reefing line exits on the port side of the lower bracket, your UV shield should be sewn onto the starboard side of the foot and leech of the sail. If the line exits on the starboard side of the lower bracket then the shield will have to be on port.

5) Assembly of the mainsail reefing system internal stay.

5a) Measure the distance from the centerline of the lower pin in hte double jaw toggle part of the top bracket assembly and the bottom surface of the lower mounting bracket. Add 1 ½” to your measurement. This is the length of your internal stay, from the center of the top eye to the end of the threaded stud. Now cut the unfinished end of the stay and assemble the stay-lok eye in accordance with the stay-lok instruction sheet.

6) Installation of the reefing system

6a) Cut the luff to the length you calculated in step 5a, minus 8”

6b) Install a reefing line (3/16”) through the sheave on the side of the lower mounting bracket, through the hole in the side of the bracket, and finally up through a hole in the spool. Tie this off with a stopper knot in the end of the furling line

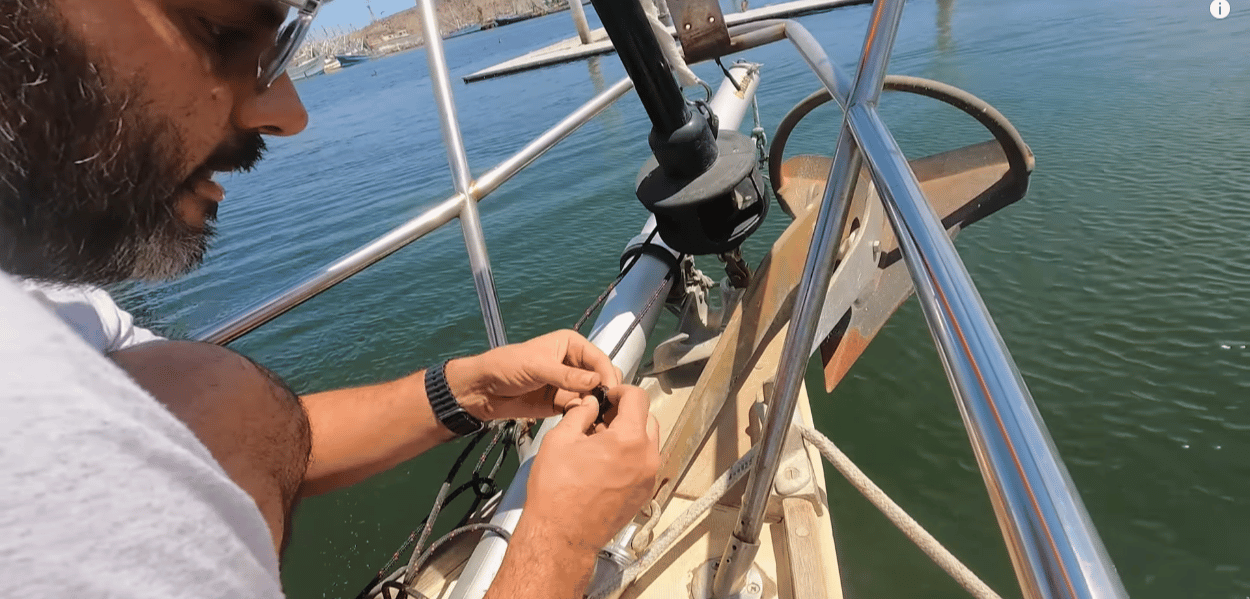

6c) With the reefing line attached, install the spool onto the bearing mounted inside the stainless steel cup which is located on the lower mounting bracket. Before raising the mainsail, wrap roughly 20 turns of the reefing line around the spool.

6d) To assemble the halyard top fitting onto the luff extrusion, first feed the de-cored end of the halyard down the luff groove opposite the sail feed slot. Now insert the stainless steel ferrule down inside the groove.

Then push the halyard top fitting over the top of the luff and secure it with the locking screw. Make sure the other end of the halyard, the end that does not have the ferrule, exits the top fitting on the same side as the sail feed slot and slides freely.

6e) Now we need to tie a messenger line that is roughly the length of the luff extrusion to the de-cored end of your halyard. We need this to raise the sail. The other end of the halyard must be pulled until the ferrule is hard against the halyard top fitting. Cut the halyard so that the sail’s head is barely below the sail feed slot in the extrusion. Melt off the end of your line to prevent fraying.

6f) Insert the bottom end of the mainsail stay through the halyard top fitting, luff, spool, and then through the lower bracket to finish. Place the bottom end of the luff extrusion into the spool.

6g) At the top of the stay there is an eye, insert the top bracket internal stay pin there.

6h) Under the lower mounting bracket we need to assemble three 5/16-24 nuts on the lower threaded end of the internal stay. The two nuts are to be used as jam nuts to hold the stay in place while tightening the tension on the stay with the third nut.Carefully, to ensure you do not bend the mast, tighten the stay until snug. Now we loosen the jam nuts and jam them against the nut already tightened to the stay.

7) At this stage we can take accurate measurements for a new mainsail. The exposed luff track is your new sail’s maximum luff. To measure the foot, we need the length from the luff sail track along the sail foot slot to the end of the boom, then subtract 6”.

Once you have measured for your new sail, you can remove the mainsail reefing system and use your old sail until your new sail arrives. Once the new sail arrives, we can continue the installation.

8) Installing the reefing track to the top of the boom

8a) At the outboard end of the boom locate the reefing track.

8b) Drill and tap through the mounting holes 10-32 threads into your boom, down through the former mainsail foot rope groove. Now we mount the track with 10-32 x 1 ½” long screws as each hole is drilled and tapped.

8c) Install the reefing car on the track

8d) Install the track end stops

8e) Install the boom reefing block with 1935 shackle, to the outboard end of the boom.

9) Install the correct lead blocks to lead the 3/16” diameter reefing line to the cockpit

10) Attach our 5/16” diameter outhaul line to the loop on the reefing car. Route the outhaul line from the reefing car up through your sail’s clew block, back through the block on the reefing car, then through the block on the outboard end of the boom, and finally forward along your boom to the mast.

Install whichever lead blocks are best to lead your 5/16” diameter outhaul line along the boom to the mast and then finally to the cockpit.

11) When running lines to the cockpit, route them to the most convenient place for you. Use some fairleads and take as few turns as possible. Increased friction from more turns than necessary will make the system more difficult to operate. Generally at least one winch should be used to assist in pulling the sail in and out. Many customers remove the main halyard winch and used for this. If you choose to run with one winch, a pair of jam or clam cleats should be positioned in front of the winch.

12) In most cases the main reefing system will not operate as easily as the jib reefing system because of the increased friction. When operating your winch, be cautious that nothing is binding and no lines are caught up on obstructions.

1) Attach your halyard to the head of your sail

2) To pull your sail up, begin by pulling down on the messenger line. It is to be attached to the decored end of your halyard while feeding the luff tape into your sail feed slot.

3) Once the sail is hoisted, you need to remove the messenger line and fasten the decored end of your halyard to the halyard anchor shackle.

4) Tension the luff of your mainsail with your tack tension line, passing 2-3 parts through your downhaul shackle on the reefing drum and the grommet on the mainsail finishing with half hitches.

5) Adjust the amount of furling line on the furling drum as needed. Once the sail is tightly furled, you should have 5 to 10 turns remaining on the furling drum.

1) Begin by casting off your halyard tension line. Then tie a messenger line that is approximately the length of your mast, to the decored end of the halyard.

2) Lower your mainsail.

Your new CDI Mainsail Reefing System is designed to be a set and forget furling and reefing system. It does not require routine maintenance, but we do recommend that you give it a thorough rinse with fresh water about once per system.

Wet lubricants of any kind are not recommended. These can cause dirt particles to get stuck in the bearing assembly causing premature wear and tear.

Dry lubricants such as a teflon spray is fine to make your furling easier.

If you are storing your mainsail reefing system for a long period of time, it is recommended that you leave your reefing system attached to the mast. Support your luff extrusion along the entire length to prevent it from sagging. Your luff must be stored straight, and flat in order for your warranty to remain valid.

Be careful not to expose the reefing system to temperatures exceeding 140°F. These temperatures frequently occur in warm climates under a boat cover.

The higher the temperature, the faster any luff bend will become permanent.

When cleaning the luff, we recommend a rag soaked with paint thinner. For any deep scrapes or dirt that has been ground into the luff, soak a rag in acetone. The reason for this, is acetone will dissolve the luff so that even deep scratches can be smoothed out.

Your new CDI Mainsail Furler is designed to be durable and trailerable.

When you trailer your boat, you can leave your mainsail reefing system installed on your mast. Make very sure that you have not positioned the mast on your boat or trailer in a position where the luff extrusion carries the weight of the mast. You must make sure that the luff extrusion is supported along its entire length to keep it from sagging. We recommend tying rope loops around the mast and luff extrusion every 2-3 ft.